Manufacturing

How big a factory does it take to build 4.5 million bicycle chains a year? It takes three, actually, and almost 200 employees. Our nearly 200,000-square-foot main factory in Osaka is where we make all the chain components for our products: plates, rollers, bushings, and pins, as well as heat-treat and polish parts for the quality, durability, and striking appearance that are our hallmarks. The main facility also houses Izumi’s extensive research and testing activities. Two other factories, each over 30,000 square feet, are dedicated to chain assembly and packing. Izumi also makes chains for automobile and motorcycle use and industrial applications.

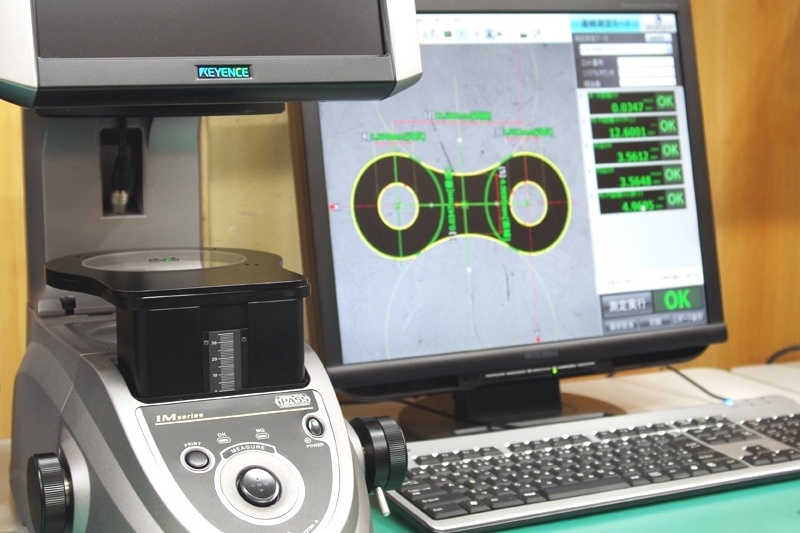

We control every part of the chain-making process, in our own factories certified to the stringent Japanese Industrial Standard. Chains start as raw steel sheet and wire. Our custom, automated machinery stamps side plates, mills rollers and cuts pins, while precision furnaces provide us with heat-treatment and surface finishes that exactly match our precise specifications for quality. Our legendary Izumi-V Super Toughness is one of just a handful of chains approved by the Japanese Keirin Association (NJS) for use on the professional keirin circuit.

Click A Photo To Explore More